Hose Management

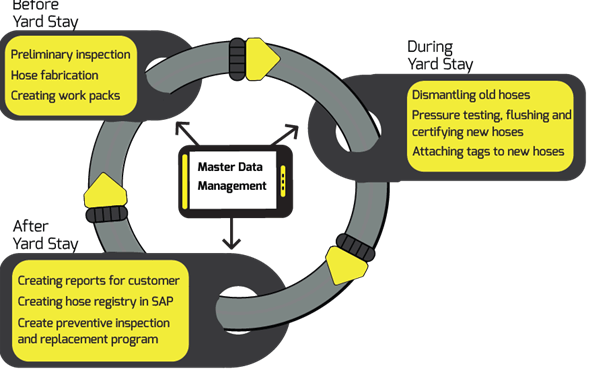

Sunmarine Engineering performs critical analysis of hoses before yard stay, during yard stay and after yard stay. This includes inspection, hose fabrication, dismantling old hoses , pressure testing and the final reporting.

Our services include performing criticality analysis of the hoses based on specifications from the customer (safety, production, environment, cost), preparing work packs, creating task lists and maintenance items etc. Our engineers can create specific hose management drawings (P&ID drawings) identifying maintainable items, thereby simplifying the maintenance planning procedure.

Benefits of Hose Management

- Trouble free start-up of systems

- Complete hose register

- Optimal data quality, ensuring good traceability and documentation.

- Ensure asset integrity and reliability.

- Keep track for certificates and manufacture documentation

- Reduce cost by avoiding vendor locking ro hose manufacturers/suppliers

- Increase efficiency during project by strategically pre-fabricating hose before project start.

Sunmarine Engineering STEEL FABRICATION

Why Choose Sunmarine Engineering?

Our hose management services include performing criticality analysis of the hoses based on specifications from the customer (safety, production, environment, cost), preparing work packs, creating task lists and maintenance items etc. Our engineers can create specific hose management drawings (P&ID drawings) identifying maintainable items, thereby simplifying the maintenance planning procedure.

Our Track Records with

Fill in the form below to request a quote

request a quote

Do you have fast requirements and looking for an experienced contactor? Act now !

SUNMARINE ENGINEERING (S) PTE LTD

First Floor, No 30 Tuas View Place

Singapore – 637 876

Email : enquiry@sunmarine.com.sg